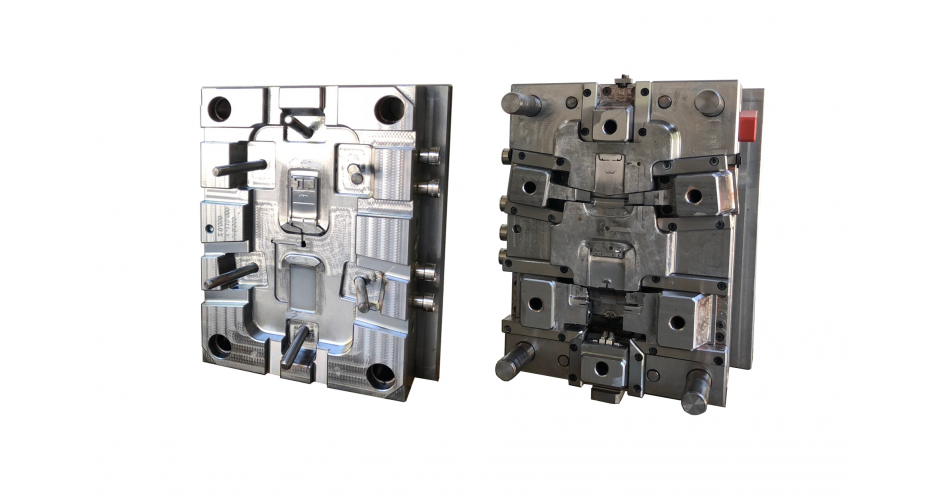

Prototype molds

Conception and development of molds destined for low production or testing with the usage of cheaper materials that allow to obtain a more suitable cost to that end.

Prototype molds

Conception and development of molds destined for low production or testing with the usage of cheaper materials that allow to obtain a more suitable cost to that end.

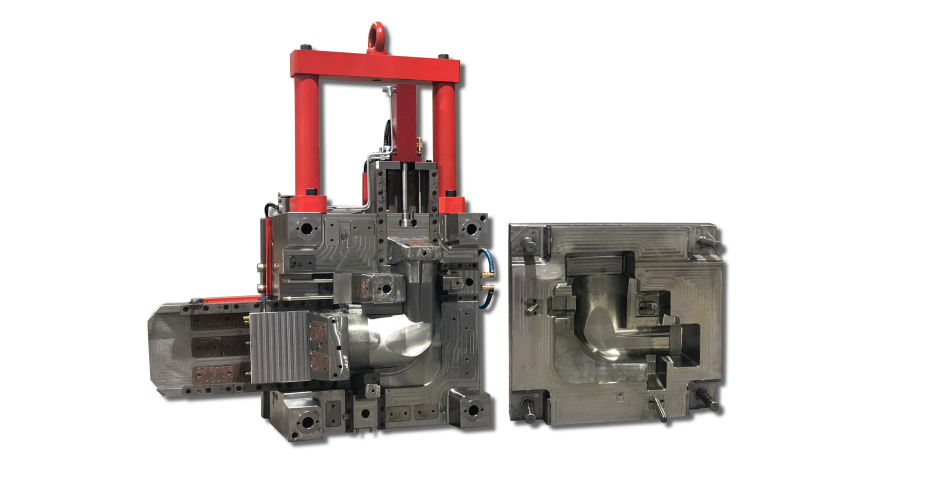

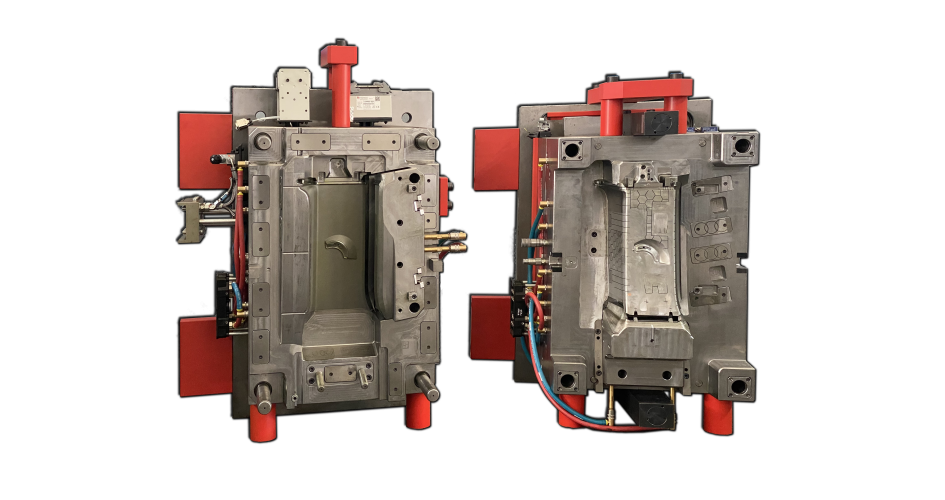

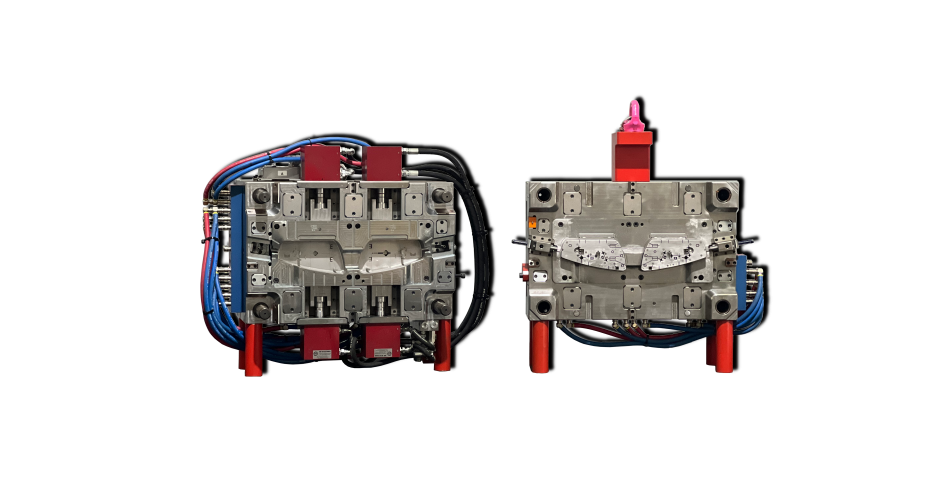

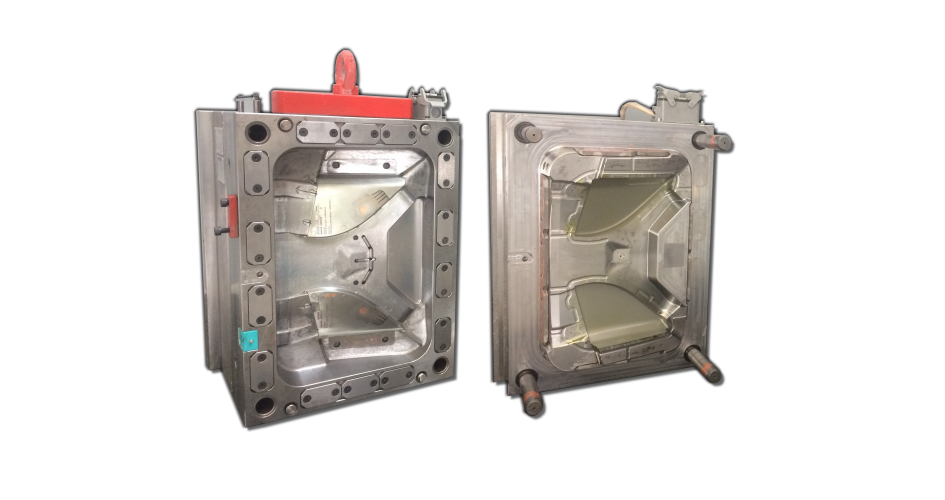

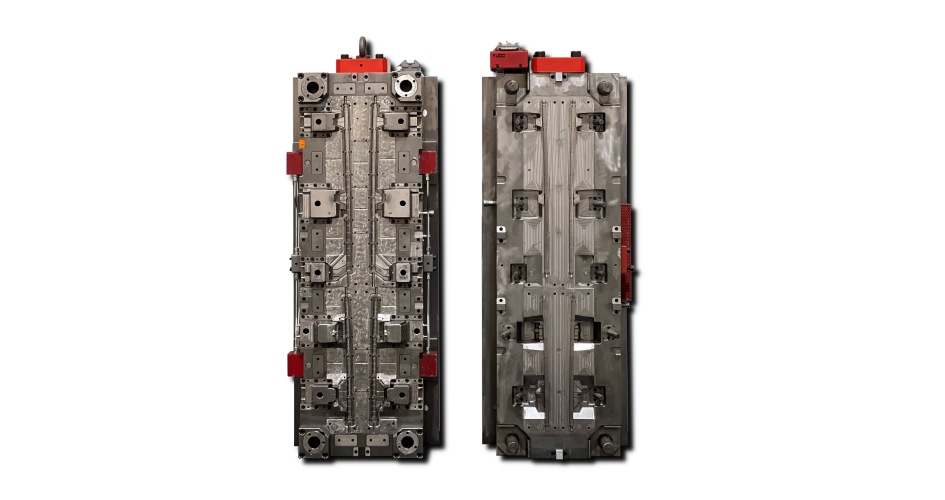

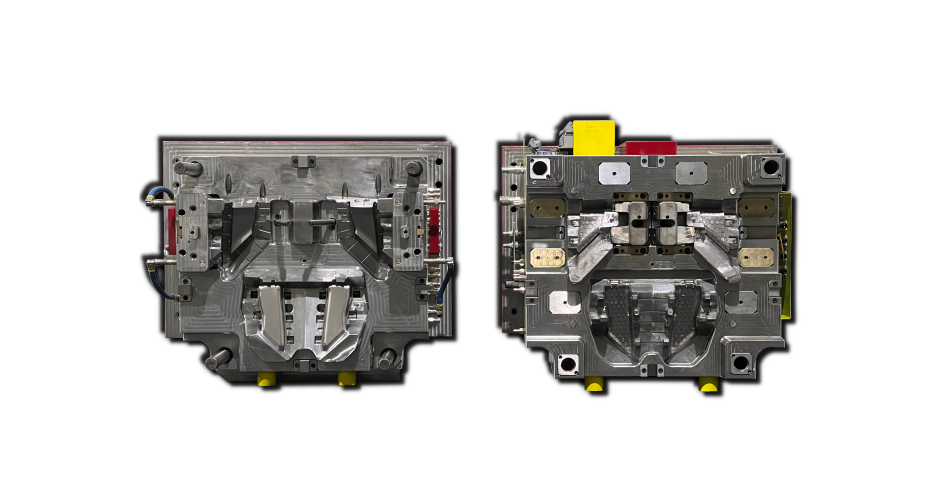

Production molds

Molds equipped to endure high production cycles demanded by the customer. Ability to produce molds up to 10 tons. Mold quality assurance and after-sales service prevail for a minimum period of 10 years.

Production molds

Molds equipped to endure high production cycles demanded by the customer. Ability to produce molds up to 10 tons. Mold quality assurance and after-sales service prevail for a minimum period of 10 years.

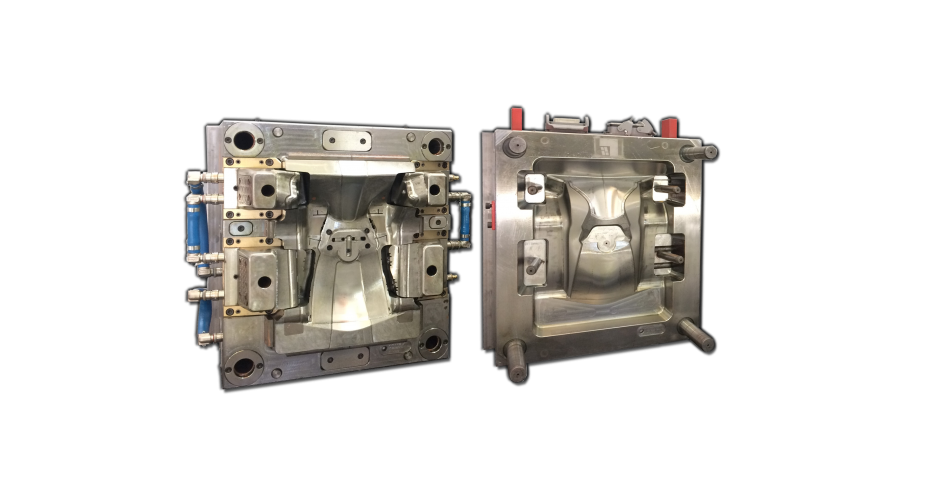

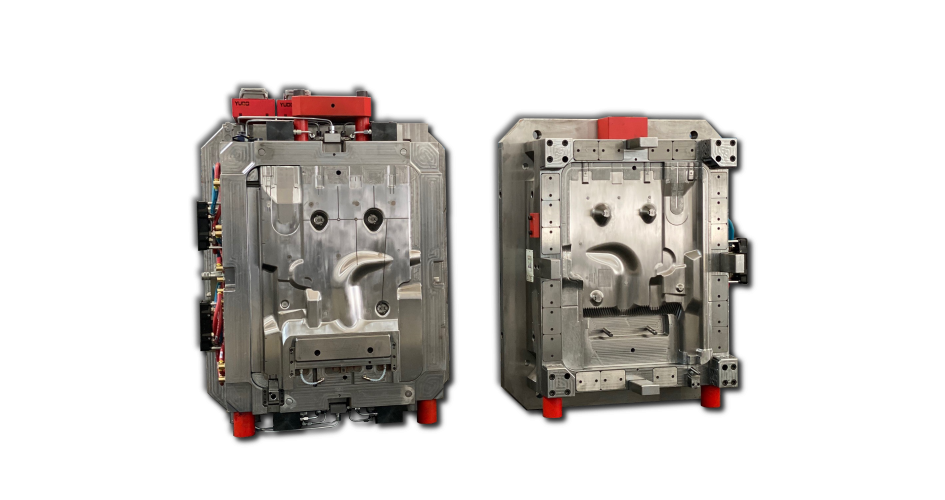

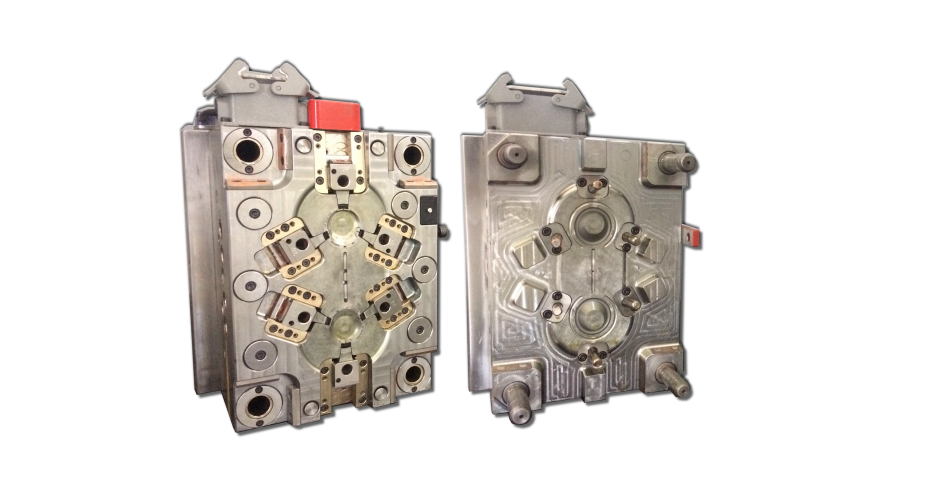

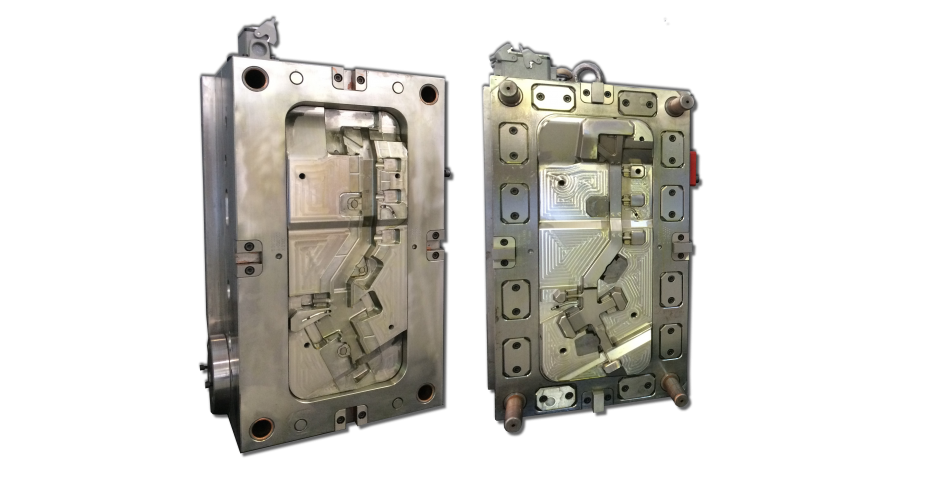

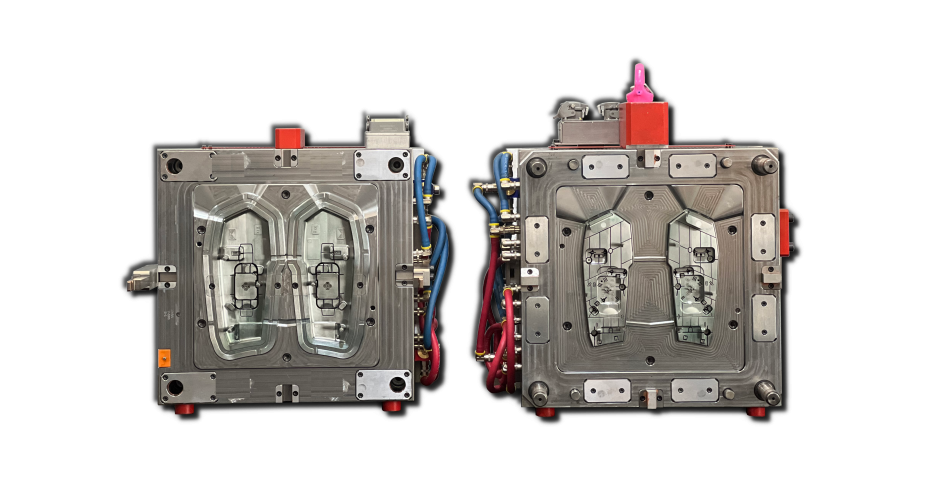

Bi-material molds

Molds conceived for the injection of two materials or colors during the moulding process without the need of additional production steps. This is due to the production of rotational, stack molds or transfer molding.

Bi-material molds

Molds conceived for the injection of two materials or colors during the moulding process without the need of additional production steps. This is due to the production of rotational, stack molds or transfer molding.

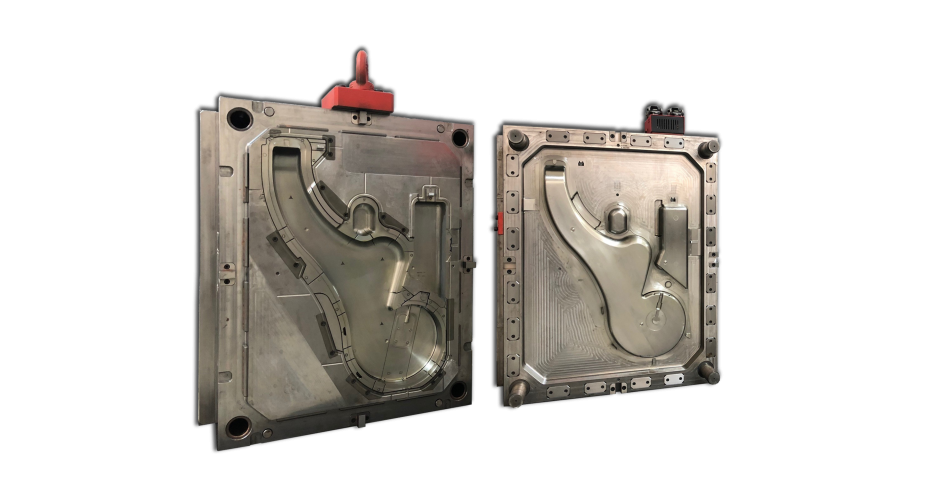

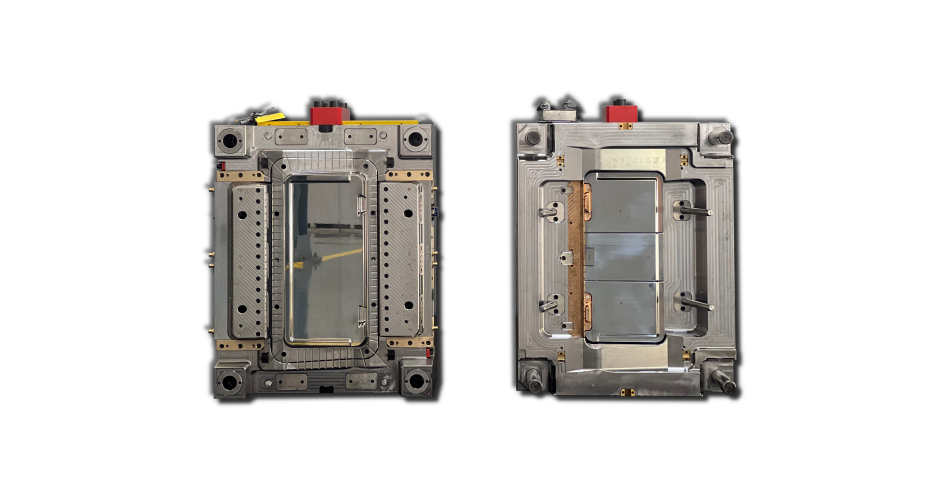

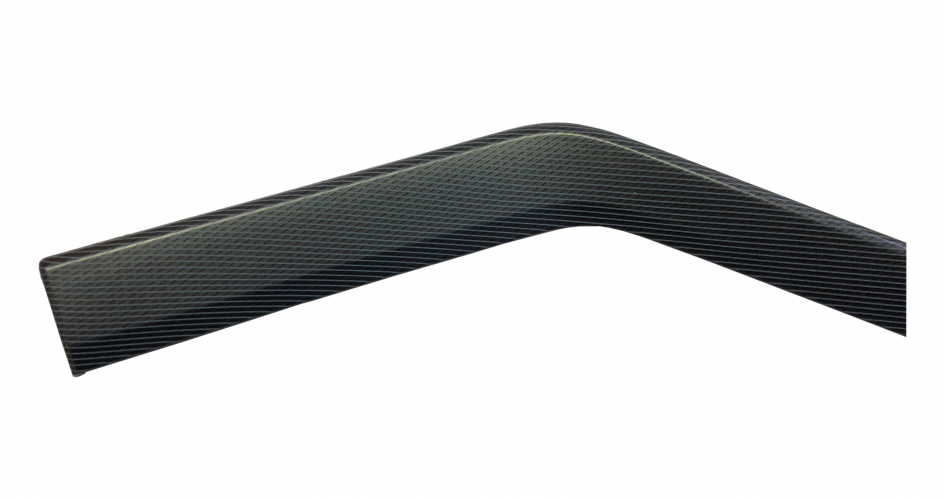

IMD molds

Development and production of molds that allow the application of decorative film inserts into the plastic part, during the injection process. Technology used in the automotive industry, mainly dashboards, central consoles and door panels, in which the plastic part comes with a customized covering.

IMD molds

Development and production of molds that allow the application of decorative film inserts into the plastic part, during the injection process. Technology used in the automotive industry, mainly dashboards, central consoles and door panels, in which the plastic part comes with a customized covering.

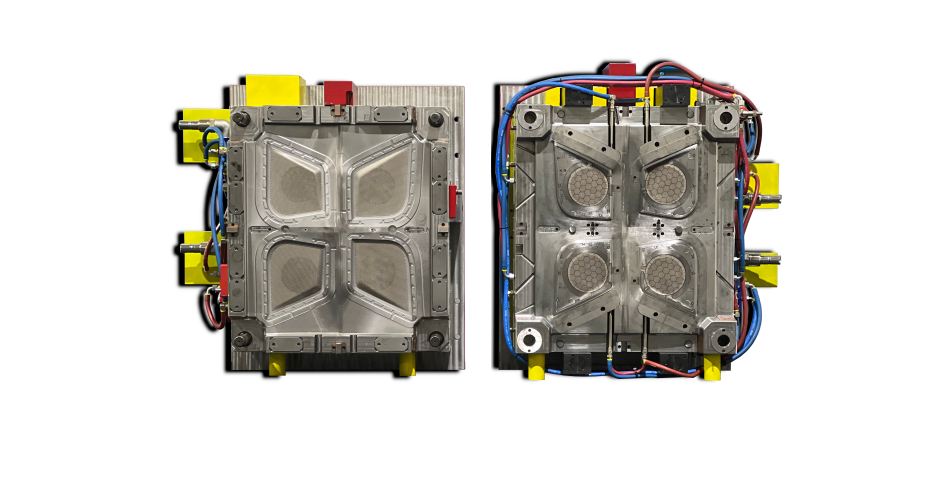

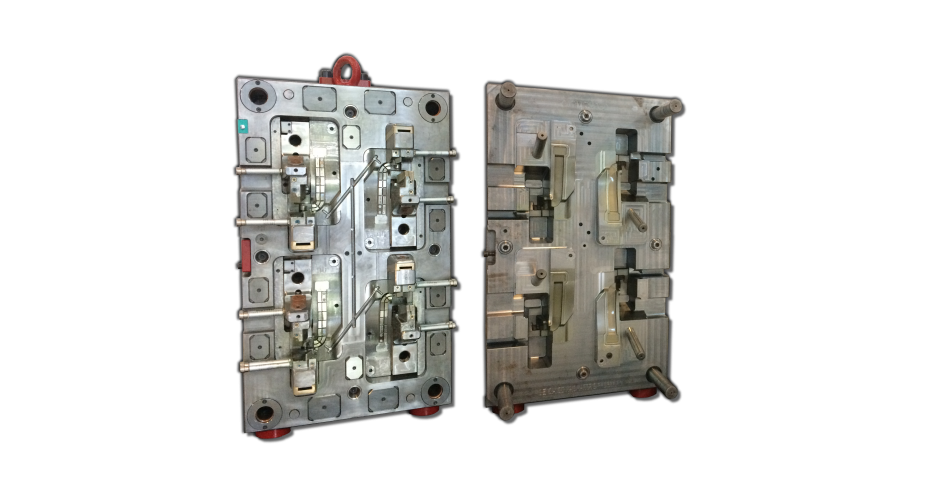

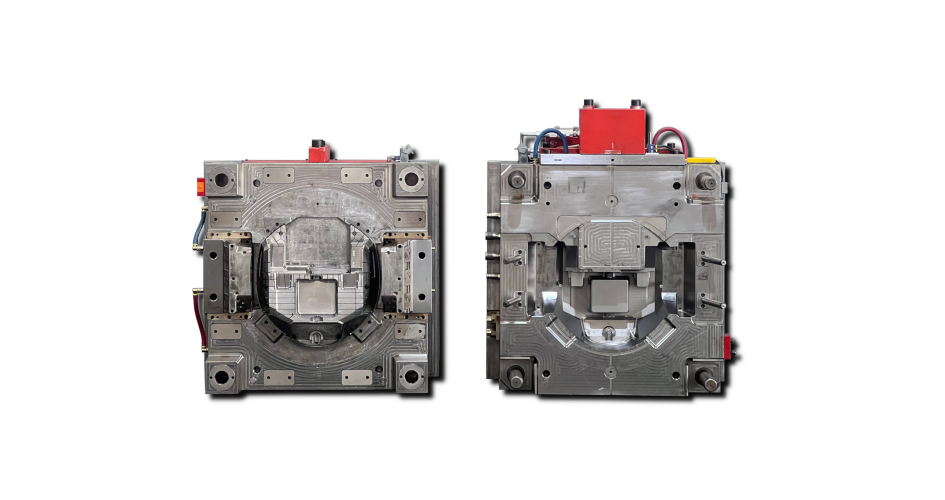

Multi-cavity molds

This is a type of mold with multiple copies of the same part and/ or symmetric parts, which is an asset for large scale productions, reducing the cost per part. The number of cavities may go up to two or more dozens.

Multi-cavity molds

This is a type of mold with multiple copies of the same part and/ or symmetric parts, which is an asset for large scale productions, reducing the cost per part. The number of cavities may go up to two or more dozens.

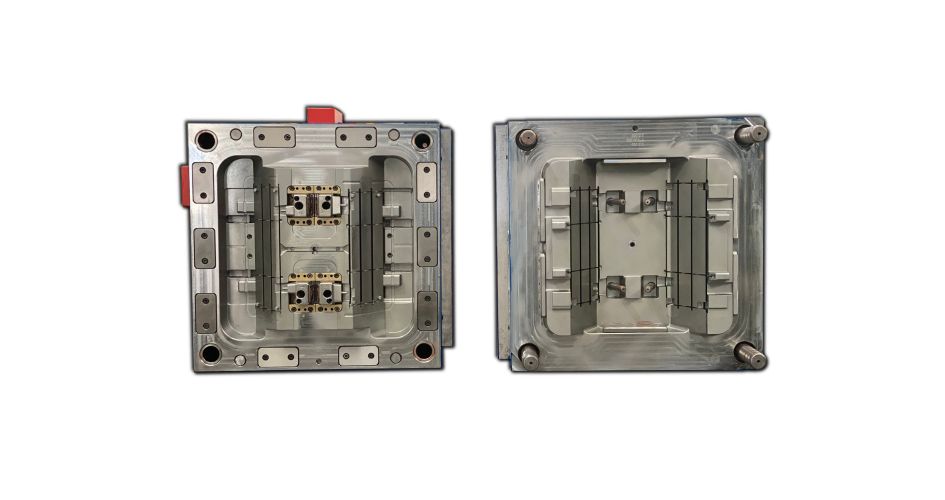

Overmolding

Molding process where a material is molded over a second material. This technique allows the connection of several types of components with the injected part, during and after the injection, avoiding further welding, gluing or setting processes.

Overmolding

Molding process where a material is molded over a second material. This technique allows the connection of several types of components with the injected part, during and after the injection, avoiding further welding, gluing or setting processes.